Fibre cement: your sustainable choice

Less raw materials, less energy, less waste.

Many buildings use large quantities of high energy produced heavy materials manufactured from substantial raw materials that result in high transport costs and generate lots of waste.

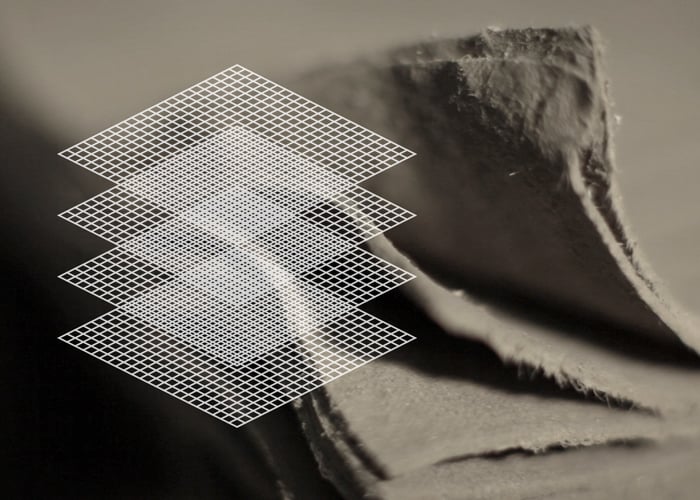

Resources and fossil fuels are diminishing. There is a need to look for creative alternatives. Clearly a case of less is more. Less raw materials, less energy, less waste. We need to think about high performing materials which are lighter, thinner and ultimately stronger.

Fibre cement technology makes this possible. It’s a high-performance composite that combines all of these advantages made of cement, water, cellulose, textile fibres, and air.

Click here for details about BES 6001 on our blog. BES 6001 is the recognised 'Framework Standard for the Responsible Sourcing of Construction Products'

As a global manufacturer, and innovator with fibre cement materials, we are always looking at ways to reduce carbon emissions, use of fossil fuels and use of resources. Our plant in Belgium is sited next to a canal to transport raw materials and reduce our C02 footprint. Our lorry’s leave our distribution hubs with full loads, or we deliver straight to site when possible. We have switched from heavy fuel to natural gas, sourcing lime and sand locally. Using cellulose from fully renewable sources, introducing a new co-generation power unit which recovers the primary energy and reuses it and aiming to have all hard factory waste recyclable.

Both manufacturing plants (Belgium and Germany) operate in accordance with ISO 14001 Environmental Management System.